composite panel design

Laminated composite structures are widely used in aviation, automotive, and ship industry.

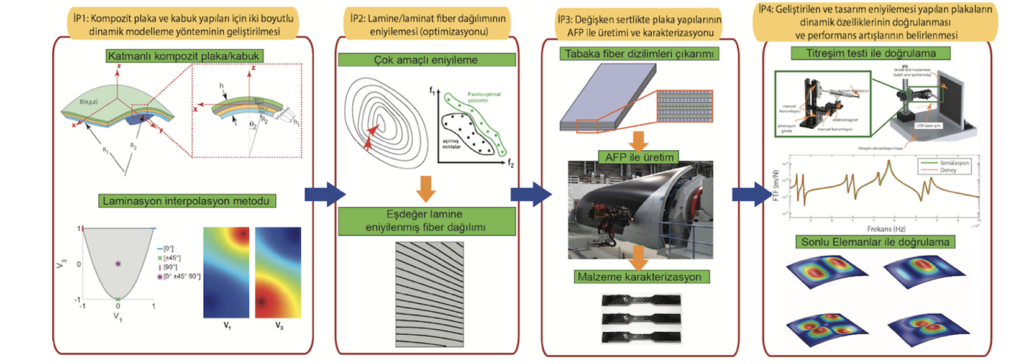

Due to their high stiffness-to-weight ratio, laminated composite structures are widely used in many fields of engineering such as aviation, automotive and ship industry. Most of the time, these laminated composite panels are exposed to dynamic forces that can cause resonances; thereby leading to excessive vibrations or even failures/malfunctions. In this project, we are working with Dr. Bekir Bediz from Sabanci University to tailor these structures in the design process and achieve an optimum design in these structures to prevent any adverse effect during their operations. We are developing parallel algorithms and high-performance software for the design process that can leverage HPC clusters.

Until recently, constant stiffness laminated composites were mostly used in these structures, where each layer of the composite structure (each laminate) was produced using a certain fiber angle. The desired design strength and dynamic properties of these flat fibers in each layer can be optimized to increase the required performance of the part. With the recent technological advancements in manufacturing of composite materials, laminates with variable stiffness properties can be produced using curvilinear fibers within each layer. Since these laminates provide better load distribution within the structure, they can perform better both statically and dynamically compared to constant stiffness composite structures.

Related Projects:

- Kompozit yapıların üç boyutlu gerilme, burkulma ve dinamik davranışının yüksek doğruluklu ve hesaplamalı olarak verimli tahmini için yeni bir spektral modelleme yaklaşımının geliştirilmesi ve kompozit yapı tasarımı eniyilemesi, TÜBİTAK 3501, 118M300, 2018-2021, PI: Bekir Bediz, Researcher: Kamer Kaya, Advisor: Melih Papila.